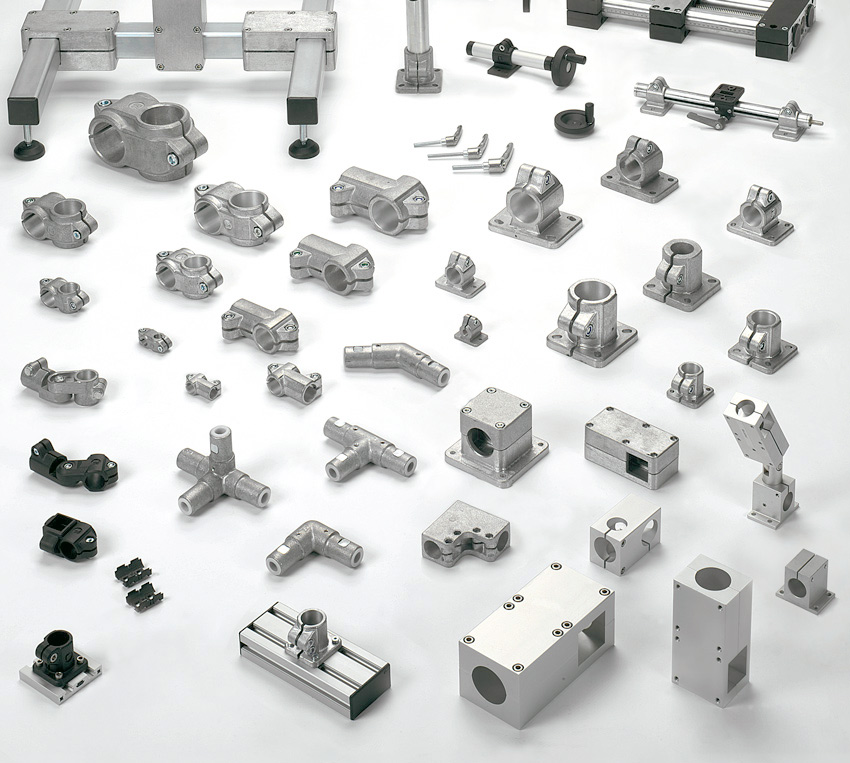

Building with aluminum square tubing connectors opens up endless possibilities for creating strong, lightweight structures. Whether you’re constructing a custom workbench, assembling a trade show display, or building industrial equipment, the key to success lies in choosing and using the right aluminum square tubing connectors.

These versatile fastening solutions transform individual pieces of tubing into robust frameworks that can handle significant loads while maintaining clean, professional appearances. Understanding how to select and implement the proper connectors will save you time, reduce material waste, and ensure your projects meet both functional and aesthetic requirements.

This comprehensive guide walks you through everything you need to know about aluminum square tubing connectors, from basic types to advanced installation techniques that professionals rely on.

Understanding Aluminum Square Tubing Connector Types

The foundation of any successful aluminum tubing project starts with selecting appropriate connectors for your specific application. Each connector type serves distinct purposes and offers unique advantages depending on your structural requirements.

Internal Corner Connectors

Internal corner connectors slide inside the tubing ends to create strong 90-degree joints. These connectors work best when you need clean exterior surfaces without visible hardware. The internal design maintains the tubing’s sleek profile while providing excellent structural integrity for frames, enclosures, and display systems.

Most internal connectors feature expansion mechanisms that secure the joint by pressing against the inner walls of the tubing. This creates a tight fit that resists both pulling and twisting forces.

External Bracket Connectors

External bracket connectors attach to the outside of tubing intersections using bolts or screws. While more visible than internal options, these connectors often provide superior strength and allow for easier assembly and disassembly.

External brackets excel in heavy-duty applications where maximum joint strength is essential. They’re particularly useful for industrial frameworks, machine bases, and structures that require frequent modifications or repairs.

Multi-Way Connectors

Multi-way connectors enable complex joints where three, four, or more tubing pieces meet at a single point. These specialized connectors eliminate the need for multiple individual joints and create cleaner, stronger intersections in complex frameworks.

These connectors prove invaluable for building truss systems, multi-level structures, and equipment frames with intricate geometries.

Key Factors for Selecting the Right Connectors

Choosing appropriate aluminum square tubing connectors requires careful consideration of several critical factors that directly impact your project’s success and longevity.

Load Requirements and Structural Demands

Calculate the maximum loads your structure will encounter, including static weight, dynamic forces, and potential impact loads. Different connector types handle various force directions differently—some excel at compression, others at tension or shear forces.

For high-load applications, consider connectors with larger contact areas or multiple fastening points. Safety factors should always account for unexpected loads or material fatigue over time.

Tubing Dimensions and Wall Thickness

Connector compatibility depends on precise tubing dimensions, including both external measurements and wall thickness. Standard sizes like 1-inch, 1.5-inch, and 2-inch square tubing each require specific connector designs.

Verify that your chosen connectors accommodate your tubing’s exact dimensions. Connectors designed for thicker-wall tubing may not fit properly on thin-wall versions, potentially compromising joint strength.

Environmental Considerations

Operating environment significantly affects connector selection and longevity. Outdoor applications require corrosion-resistant materials and finishes, while indoor use may prioritize appearance over weather resistance.

Temperature extremes, chemical exposure, and humidity levels all influence material choice and connector design. Stainless steel connectors offer superior corrosion resistance, while anodized aluminum provides good protection with lighter weight.

Step-by-Step Installation Process

Proper installation techniques ensure maximum connector performance and joint longevity. Following systematic procedures prevents common mistakes that compromise structural integrity.

Preparation and Planning

Begin by cutting all tubing pieces to exact lengths using appropriate cutting tools. Clean cut ends remove burrs and debris that could interfere with connector fit. Square, smooth cuts ensure proper connector seating and optimal load distribution.

Organize all components before assembly begins. Having connectors, fasteners, and tools readily available streamlines the installation process and reduces errors.

Assembly Sequence and Techniques

Start assembly with the most critical structural elements, typically the main frame or base components. Install connectors on individual pieces before attempting final assembly when possible.

For internal connectors, slide them into tubing ends and position them at the correct depth before tightening expansion mechanisms. External connectors require careful alignment to ensure all bolt holes line up properly.

Use appropriate torque specifications for all fasteners. Over-tightening can damage tubing or connectors, while under-tightening creates loose joints that may fail under load.

Quality Control and Testing

Inspect each joint after assembly to verify proper connector seating and fastener tightness. Check for any gaps, misalignments, or loose connections that could indicate installation problems.

Test assembled structures with gradually increasing loads when possible. This approach identifies potential weak points before full operational loads are applied.

Common Installation Mistakes to Avoid

Even experienced builders can make mistakes that compromise connector performance. Understanding these pitfalls helps ensure successful installations.

Improper Connector Sizing

Using connectors designed for different tubing sizes is a frequent error that leads to poor fit and reduced strength. Always verify connector specifications match your exact tubing dimensions.

Forcing undersized connectors into tubing can cause splitting or deformation. Oversized connectors create loose joints with inadequate load transfer.

Inadequate Fastener Selection

Choosing inappropriate bolts, screws, or other fasteners compromises joint strength regardless of connector quality. Match fastener grades and specifications to expected loads and environmental conditions.

Mixing fastener materials can create galvanic corrosion problems in outdoor or marine environments. Use compatible materials throughout the assembly.

Poor Surface Preparation

Failing to clean tubing ends or connector surfaces before assembly allows contaminants to interfere with proper fit. Oil, dirt, or metal shavings can prevent connectors from seating correctly or cause premature wear.

Maintenance and Long-Term Performance

Regular maintenance extends connector life and ensures continued structural integrity throughout your project’s service life.

Inspection Schedules

Establish regular inspection intervals based on load conditions and environmental exposure. High-stress applications may require monthly checks, while low-load indoor structures might need only annual inspections.

Look for signs of loosening fasteners, connector wear, or corrosion damage. Address any issues immediately to prevent progressive failure.

Preventive Maintenance Practices

Apply appropriate lubricants to moving parts or adjustable connections to prevent seizing. Use products compatible with aluminum and any protective coatings.

Replace worn or damaged connectors before they compromise structural integrity. Keep spare connectors available for critical applications where downtime must be minimized.

Optimizing Your Aluminum Tubing Projects

Mastering aluminum square tubing connectors opens up remarkable possibilities for creating strong, versatile structures that serve your exact needs. Success depends on understanding connector types, selecting appropriate components for your specific application, and following proven installation techniques.

Remember that quality connectors represent a small fraction of total project cost but determine overall performance and longevity. Investing in proper connectors and installation tools pays dividends through years of reliable service and reduced maintenance requirements.

Start your next project by carefully evaluating structural requirements and environmental conditions. This foundation ensures you select connectors that will deliver the performance your application demands.