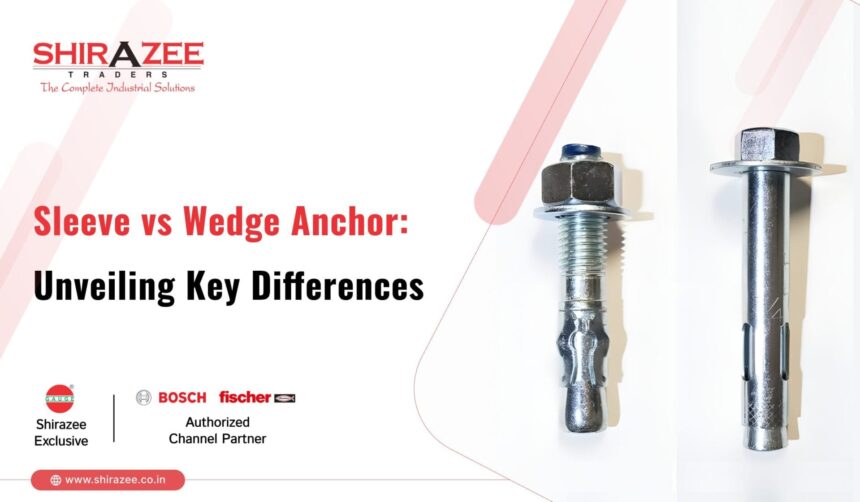

Introduction to Sleeve Anchors and Wedge Anchors

When it comes to securing materials and structures, the right anchor can make all the difference. Two popular choices in the anchoring world are sleeve anchor vs wedge. But how do you know which one is best for your specific project? Each type has its own unique features that cater to different needs, environments, and load requirements.

In this blog post, we’ll dive deep into the specifics of sleeve anchor vs wedge. We’ll explore their differences, strengths, installation processes, applications, costs—everything you need to make an informed decision for your next job. Whether you’re a DIY enthusiast or a seasoned professional, understanding these two types of anchors will empower you to choose wisely and achieve robust results. Let’s get started!

Differences between sleeve anchor vs wedge

sleeve anchor vs wedge anchors serve similar purposes but have distinct differences that can influence your choice.

sleeve anchor vs wedge consist of a threaded bolt encased in a sleeve. When installed, the sleeve expands against the base material, creating a strong hold. They work well in concrete or masonry applications.

Wedge anchors, on the other hand, utilize a tapered end to create tension when tightened. This design allows for deeper embedment into the material, leading to superior load-bearing capabilities in many situations.

While both types offer reliable performance, their installation requirements differ significantly. sleeve anchor vs wedge require less drilling depth compared to wedge anchors which need more precise placement.

Additionally, sleeve anchors are often easier to remove and replace without damaging surrounding materials. Wedge anchors may not be as forgiving once installed due to their permanent nature during removal.

Strength and Load Capacity Comparison

When comparing strength and load capacity, sleeve anchors and wedge anchors present distinct profiles. Sleeve anchors typically excel in shear loads. They distribute weight across a wider area within the base material.

On the other hand, wedge anchors are known for their superior tensile strength. This makes them ideal for heavy-duty applications where pulling forces are significant.

The actual load capacity varies based on factors like anchor size, material quality, and installation depth. It’s essential to consult manufacturer specifications for precise figures relevant to your project.

Consider environmental conditions as well; some materials resist corrosion better than others. Depending on exposure to moisture or chemicals, one may outperform the other over time.

Understanding these differences can guide you in selecting an anchor that best meets your needs without compromising safety or performance.

Installation Process for Sleeve Anchors and Wedge Anchors

Installing sleeve anchors requires precision. First, drill a hole into the concrete or masonry surface using a hammer drill. The diameter and depth of the hole depend on the anchor size.

Next, insert the sleeve anchor into the hole until it’s flush with the surface. It’s crucial to ensure that no debris is left inside to avoid compromising its hold. Then, tighten the nut and washer against your fixture; this action expands the sleeve within the base material.

Wedge anchors follow a slightly different approach. Start by drilling an appropriately sized hole for your selected wedge anchor. Clean out any dust or loose particles from this cavity to promote optimal grip.

Insert the wedge anchor through your fixture and tap it in gently with a mallet if needed. Tighten down on it using a wrench until secure—this compresses wedges against sides of your drilled hole, ensuring maximum strength during load-bearing tasks.

Applications and Uses of Sleeve Anchors and Wedge Anchors

Sleeve anchors are versatile and ideal for many installations. They work well in concrete, brick, and block applications. You’ll often find them used in securing railings, signs, or electrical equipment to walls.

Their design allows expansion within the base material. This makes sleeve anchors a great choice for projects where vibration might be an issue.

On the other hand, wedge anchors excel in heavy-duty situations. These bring superior holding power under extreme loads. Commonly seen in structural applications like anchoring steel beams or machinery to concrete foundations.

Wedge anchors suit seismic zones due to their robust grip on materials. They can also tolerate high tension forces effectively.

Choosing between these options depends largely on your project’s requirements—understanding their strengths will ensure you make the right decision for your needs.

Cost Analysis: Which Anchor is More Affordable?

When comparing sleeve anchors and wedge anchors, cost is often a crucial factor. Sleeve anchors typically come at a lower price point, making them an attractive option for budget-conscious projects. Their affordability makes them popular among DIY enthusiasts and contractors alike.

Wedge anchors can be pricier due to their robust design and higher load capacities. This increased durability often justifies the extra expense in heavy-duty applications where safety is paramount.

It’s essential to consider not only the initial purchase price but also potential long-term costs. If your project demands frequent maintenance or replacement, opting for a more durable anchor may save money over time.

Analyzing your specific needs will guide you in choosing the most economical solution without compromising on quality or safety.

Choosing the Right Anchor for Your Project

Selecting the right anchor for your project can feel overwhelming. It’s essential to consider several factors before making a decision.

First, assess the materials you’ll be working with. Sleeve anchors are excellent for concrete and masonry, while wedge anchors excel in heavy-duty applications where maximum holding power is required.

Next, think about load requirements. If you anticipate high loads or shear forces, wedge anchors may suit your needs better due to their superior strength.

Don’t overlook installation ease as well. Sleeve anchors are generally easier to install, especially in tight spaces or when precision matters.

Evaluate environmental conditions too. Certain projects may require corrosion-resistant options that fit within specific guidelines.

Aligning your choice with project specifications ensures safety and durability in the long run.

Conclusion

Choosing between sleeve anchors and wedge anchors depends on your specific needs. Each type has distinct advantages that can cater to different applications.

Consider the environment where you’ll be using these anchors. Factors like material, load requirements, and installation conditions play a significant role in making an informed decision.

Testing each option may help you understand its performance better. Often, hands-on experience provides clarity beyond theoretical comparisons.

Remember to evaluate long-term durability as well. The right choice should combine strength with ease of use for your particular project.

Seek advice from professionals if you’re uncertain about which anchor suits you best. Their expertise might guide you toward the most appropriate solution for your tasks ahead.

FAQs

When it comes to choosing between sleeve anchors and wedge anchors, there are several factors to consider. Each type of anchor has its strengths and weaknesses that may suit different applications better. Understanding the key differences will help you make an informed decision.

Now, let’s address some commonly asked questions regarding sleeve anchors and wedge anchors.

What is a sleeve anchor?

A sleeve anchor consists of a bolt with a hollow sleeve that expands against the sides of the hole as it’s tightened. It provides strong holding power in concrete or masonry surfaces.

Are wedge anchors stronger than sleeve anchors?

Wedge anchors generally have higher load capacities than sleeve anchors due to their design, which allows them to expand securely within the base material.

Can I use a wedge anchor in brick?

While it’s possible to use wedge anchors in brick, they perform best in solid concrete. For softer materials like brick or block, other anchoring solutions might be more suitable.

How deep do I need to drill for a sleeve anchor?

The depth varies based on the diameter and length of your specific screw but typically should be at least 1/4 inch deeper than the length of your selected anchor.

Is installation easier for one over the other?

Sleeve anchors can often be quicker and simpler to install since they require only drilling into concrete without needing special tools for expansion. Wedge bolts usually need precise positioning when hammered into place during installation.

How do I know which one is right for my project?

Consider factors such as load requirements, substrate material, environmental conditions (like moisture), and whether you’re working with horizontal or vertical installations before making your choice.

Hopefully these insights clarify any lingering doubts about selecting between sleeves versus wedges!